Unlocking the Potential of Linear Stages with Linear Motor Modules

linear stages with linear motor

The linear motor module is a valuable tool for industrial manufacturing and robotics applications. This powerful device can be used to move parts in linear directions, allowing for faster and more precise production processes. By combining advanced technology with a strong magnetic field, linear motor modules are able to move the most complex components along a straight line. In this article, we’ll explore the potential of Rapid shutdown solar panels modules and how they can revolutionize your industry.

What Is a Linear Motor Module?

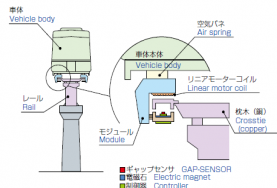

A linear motor module is a compact device that consists of an external coil or linear stator and one or several permanent magnets. This advanced device can be used to move parts in linear directions and can be adjusted for speed and precision. Thanks to their simple design, linear motor modules are highly efficient and require less energy than traditional motors.

The primary benefit of using a linear motor module is its ability to enable precisely controlled linear movements, making it ideal for achieving high-accuracy tasks. This makes it perfect for fast-paced manufacturing and assembly lines as well as delicate medical procedures such as laser surgeries.

Applications of Linear Motor Modules

Linear motor modules have many applications across various industries. In manufacturing, they can be used to move parts along conveyor belts, palletizers, and automated feeding systems with incredible speed and accuracy. In the automotive industry, linear motors can be used to adjust car engines while they’re still running, allowing mechanics to make quick and effective repairs.

In addition, these devices can also be used in robotic systems for pick-and-place operations, as well as industrial automation, material handling, and even medical research. With such a wide range of uses, it’s no wonder why linear motor modules are becoming increasingly popular.

Advantages of Linear Motor Modules

Linear motor modules offer numerous benefits over other forms of linear motion control. They’re designed to operate without lubrication, which helps reduce maintenance costs and improves overall efficiency. Additionally, linear motor modules are smaller and lighter than traditional motors, allowing them to fit into tighter spaces and reduce the total system size.

Furthermore, linear motor modules allow for infinite acceleration and deceleration rates, which can be beneficial in applications where rapid changes in direction are required. This feature is particularly useful in automated assembly lines, where a sudden stop or change of direction could result in serious damage.

Current Trends in Linear Motor Modules

As the demand for greater automation and higher speeds continues to grow, so too does the need for advanced linear motor modules. In order to meet the ever-increasing needs of modern industrial manufacturing, manufacturers are turning to innovative technologies such as digital twin modeling, machine learning, and 5G communication networks in order to develop smarter, more agile linear motor modules.

In recent years, the trend has shifted towards integrated systems that combine the linear motor module with other components such as sensors, controllers, and actuators. These integrated systems help to improve overall performance by allowing multiple devices to work together in perfect harmony, thereby eliminating any potential errors that could otherwise occur.

Conclusion

By combining advanced technology with a strong magnetic field, linear motor modules hold the potential to revolutionize industrial production and automate a variety of processes. These powerful and intuitive devices offer a range of advantages over other forms of linear motion control, making them the preferred choice for manufacturing and robotics applications. Moreover, as demand for better automation continues to increase, manufacturers are turning to innovations such as digital twin modelling and machine learning in order to develop smarter and more agile linear motor modules.